Manufacturing PCBA to focus on the research, development, and market development of new products.

By comparison PCB electronic products are produc by selecting competent electronic processing companies.

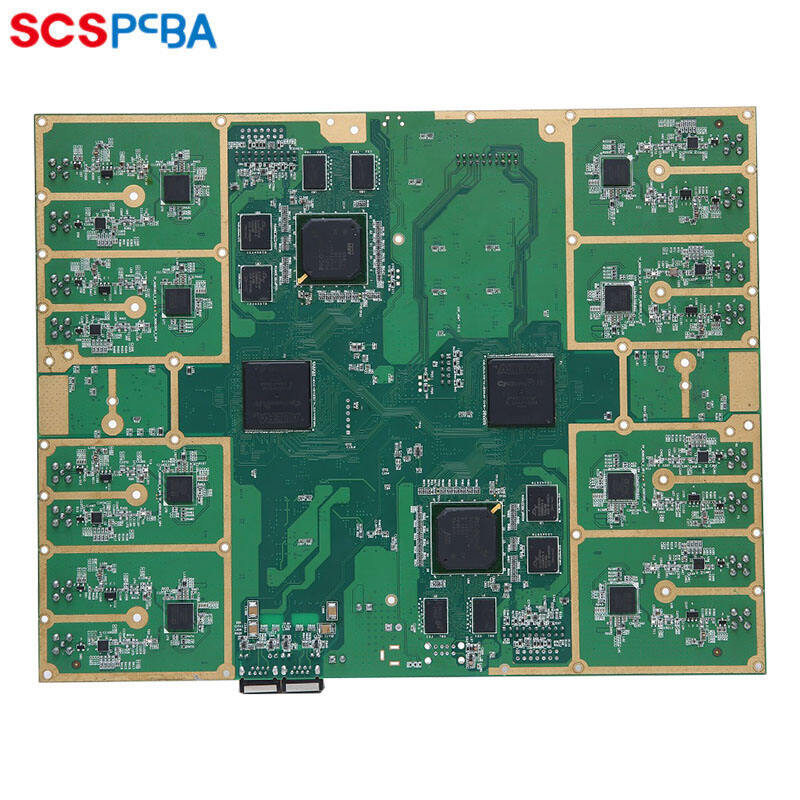

By all means the Circuit Board Assembly process consists of the procurement of material, the assembly of SMT chips, the assembly of DIP plugs.

The testing of PCBAs, the assembly of finished products, and the distribution of finished products.

Assembling prototype PCBs involves the following steps:

Sign a contract and determine cooperation

Before Pcba Manufacturing, a cooperation contract was sign after the parties negotiate by Electronic Manufacturing Services profiders.

Provide information on the processing of the customer’s order

By all means the customer places an order, and a bill of materials. a PCB file, a Gerber file, a graph, and PCBA test plans are provided.

Material procurement

Customers order electronic component materials, PCB boards, steel mesh, and fixtures from the electronic processing factory.

Receiving, inspecting, and processing materials

As soon as the material reaches the PMC, it is inspect, processed, and delivered for production.

Processing of SMT chips and DIP plug-ins

In order to complete PCB processing and soldering, there will be quality inspection in every step of the process, from solder paste printing to patching, reflow soldering, AOI inspection, DIP plug-ins, and wave soldering.

PCBA test

In addition to testing according to the customer’s test plan, the electronic processing factory repairs the discovered defective products based on its own testing process.

Pcb Assembly | Pcb Assembly Services | One Stop Pcb Assembly | Pcb Assembly China | Pcb Fabrication Assembly | Printed Circuit Board Assembly | Electronic Components | Pcb Assembly Manufacturer | Prototype Pcb Assembly