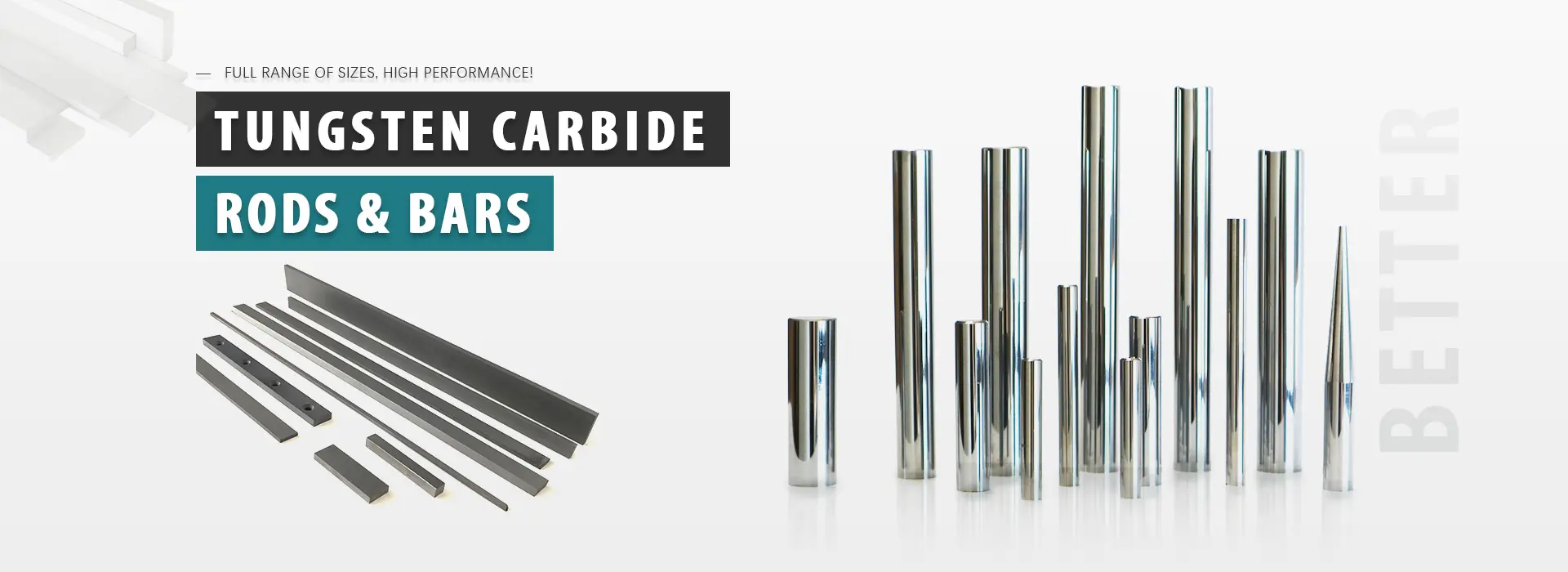

Zhuzhou Better Tungsten Carbide Provides Excellent Range of Tungsten Strips

Zhuzhou Better Tungsten Carbide is renowne agency that is production extraordinary types of carbide die. We are subjecte to substantial fine manipulate measures to make certain compliance with all technical specifications, beginning from certification to ensure the uncooked materials’ purity and bodily properties, via rigid production controls, to advanced size capabilities of the very last product.

We, producer of precision-floor, put on parts, gadget parts and dies for business programs. Specializing in tungsten carbide, silicon carbide, and ceramics substances, have a proven potential to arise underneath the stress of wear and tear, corrosion, abrasion, and surprise, so, grinding to the tightest tolerances in the industry. If you need to buy Tungsten carbide drawing dies, the specialists will assist you select the right one. We are providing in highest quality manufacturing to fulfil the client’s industrial needs.

Tungsten carbide drawing dies

We have advanced unique grades of ceramics and carbides, especially tailored for extraordinary provider conditions, to ensure most desirable performance and lengthy existence for water jet pump parts and components. Our in-residence machines are successful to build maintained right in our plant. Our agency gives widespread shopping for energy of raw materials with our lengthy-term enterprise partners. Tungsten Carbide Ground Bar manufacturing experts are able to manufacturing the rods as customer-precise desires. You could speak your custom designed desires with the clients.

Tungsten Carbide Ground Bar

Tungsten carbide rods are design and manufacture in our own workshop. So we will correctly provide perfectly directly, cut-to-duration cord for the largest or smallest orders at an less expensive value. We can engineer a turnkey device and train your workforce in its operation. Our business enterprise may even offer a fee-benefit analysis to determine whether or not a service version or in-house manufacturing quality meets your financial needs. To know greater about the organisation, you could go to our reliable website each time.