Using Tungsten Carbide Dies & Tool

Slicing device grades of carbides are similarly subdivide into two organizations: cast-iron carbides and metal-grade carbides. As their call implies, cast-iron carbides are specifically made for slicing solid iron substances. Those carbides are extra proof against abrasive put on, shielding the carbide cutting tool from area put on because of the excessive abrasiveness of cast-iron.

Tungsten carbide strips, however, are in particular made to withstan cratering and heat deformation that can be cause by the long chips of metallic on better reducing speeds. Whichever grade of carbide is utilize in a carbide slicing tool, the primary carbide fabric use in its manufacture is tungsten carbide (WC) with a cobalt binder. Tungsten carbide well known for its hardness and resistance to abrasive wear. Cobalt, then again, is use to further improve the device’s surface.

What is Carbide?

In chemistry, carbides discuss with any organization of compounds made from carbon and a further element that can be a steel, boron, or silicon. There are genuinely many compounds belonging to this group, some of the greater popular of which incorporates:

•Calcium Carbide

•Aluminium Carbide

•Silicon Carbide

•Tungsten Carbide

•Iron Carbide

•industrial makes use of Carbide

In the twentieth century, Tungsten carbide dies have been use for a whole lot of commercial programs. so, Carbides use in business programs are regularly referre to as cemente carbide merchandise and are classified in 3 essential grades:

•Wear grades

•Used mainly in dies, machine and tool guides

•Impact grades

•Better surprise resistance carbide products used for dies, especially for stamping and forming

•Cutting device grades

•Carbide gear used for reducing

Benefits of Carbide cutting equipment

•Longevity

•Top notch resistance to abrasion

•Advanced put on resistance

•Resistance to cratering

•Resistance to thermal deformations

•Excessive modulus of elasticity

•Chemical inertness

•Torsional strength two times that of HSS

•Compressive electricity

Other editions

Aside from Cemente carbide rod and cobalt, other alloying substances inside the manufacture of carbide slicing equipment. Among them is titanium carbide and tantalum carbide. Titanium carbide helps the carbide reducing device to resist cratering while tantalum carbide can reduce warmth deformations inside the tool. Also generally use in the cutting industry nowadays are coate carbide reducing tools.

Apart from the simple carbide substances, titanium carbide, titanium nitride, ceramic coating, diamond coating or titanium carbonatite are use as coating substances. so, The exclusive coating materials resource the carbide cutting device differently, despite the fact that they may be generally use to further reinforce the cutting tool.

As the demand for well cutting tools growth, cutting tool suppliers also incessantly develop products that can pass producers’ demands. Through the years, a lot of resources for the manufacture of cutting tools have been teste upon; some have passed the values while others were simply droppe. For more great carbide cutting tool, products and resources check out our official website.

Read it also:

Zhuzhou Better Tungsten Offer High End Carbide Wire Range

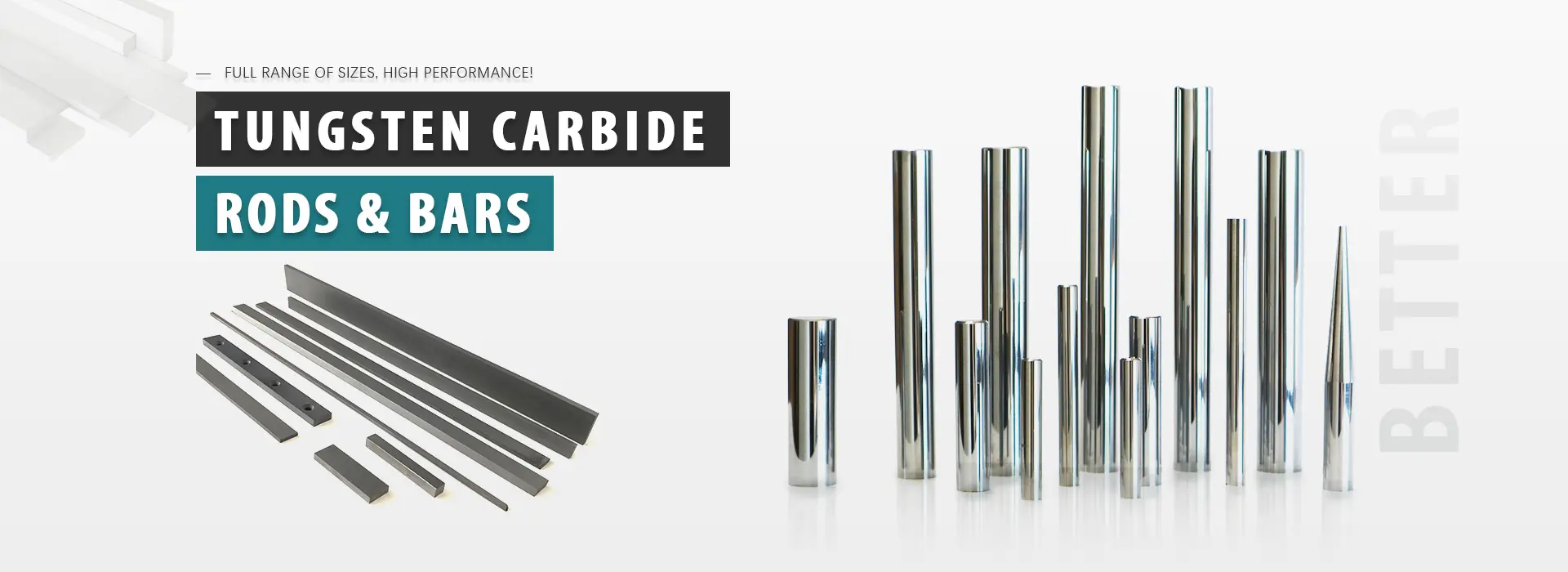

Tungsten Carbide Rods and Bars Available At An Affordable Rates