What Is a Drill Bit?

A drill bit is a hole-making rotary cutting instrument. The drill bit’s point makes contact with the material you are drilling into, and the drill chuck’s jaws hold the bit’s shank in position at the back.

Anchor Drill bits come in various shapes and sizes, enough to occupy an entire aisle in a hardware shop. We’ll concentrate on those most frequently utilized in do-it-yourself projects for our needs.

What Size drill bit to use for drywall Anchors

The Size of the Anchor Drill bit determines the hole’s diameter. As a result, it’s essential to check the anchor’s front before drilling by comparing the drill bit’s shank measurement. It should ideally have an equivalent or slightly bigger diameter than the screw. Usually, the anchor’s box will list its diameter.

What Size Drill bit to use for concrete Anchors And Toggle bolts

The holes for toggle bolts and concrete anchors should be the same Size. For instance, the spot for a 3/8 concrete anchor should be 3/8 or somewhat bigger. For self-tap drywall anchors, however, a drill bit is not required.

Types of drill bits

Twist Drill Bit: This type of drill bit is the most popular and is utilized in many constructions and home improvement projects. They work on wood, metal, and plastic.

Brad and Pilot Point Bit: The exit hole on this drill bit is made by a W-shape-centered tip, making it the best drill bit for do-it-yourself wood projects. It can build cabinets, furniture, and other woodworking tasks.

Countersink Drill Bit: This is a top-notch tool for cabinetry and general carpentry. They’re intended to be inserted into countersunk holes. A countersink creates a conical hole that matches the screw’s angle.

Step Drill Bit: This drill bit is ideal for drilling pilot holes in metal and wood. Allows for a single drill bit to create holes of various sizes.

Masonry Drill Bit – suitable for masonry, brick, and concrete. It is used to build and repair dwellings and performs best when used with a hammer drill.

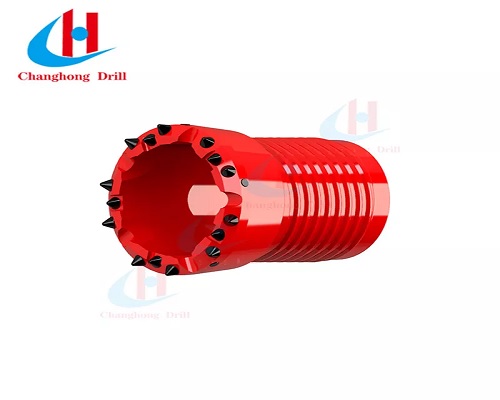

Down The Hole Drilling

A drill rod is equipped with a hammer at its lower end for down the hole drilling. Compressed air activates the hammer, positioned on the drill bit, and drives it into the ground as it revolves and impacts. In addition, The drill cuttings are loosen and carry upwards by a flushing current. Similarly this technique typically penetrates giant boulders and extremely hard rock.

Process principle of cased Down the Hole Drilling

Setting the Down The hole Drilling hammer with drill road and casing on the drilling point.

Complete cased borehole.

Withdrawal of the drill road Down, The Hole Drilling hammer, and a pilot bit out of the casing.

How Carbide Button Bit works

Most metal products must be cool to average temperature after being forged or cast at high temperatures. In the past, this was accomplish by quenching the objects in the water, but contemporary cryogenic procedures offer a more precise treatment method.

Carbide Button Bit Using a cryogenic liquid or gas, the metal is cool to cryogenic temperatures (-238 °F or lower) as part of a one-time cryogenic treatment. It can then be heat to a higher temperature once again before being allow to cool naturally.

Can you sharpen carbide drill bits?

Even the highest-quality drill bits will eventually become worn out, so you must choose between sharpening or replacing them. So Carbide drill bits are expensive. Therefore it’s probably worthwhile to sharpen them.

Similarly It might be additional economical to pay a professional to perform it if you don’t have access to a grinding wheel. Therefore, even while you can sharpen carbide drill bits, doing so takes specialized equipment, and doing it well may require some expertise.

Get To Know More About Our Products:-

Rock Drilling Bit | Button Drill Bit | Button Bit | Rock Drill Bit | Tapered Drill Bit